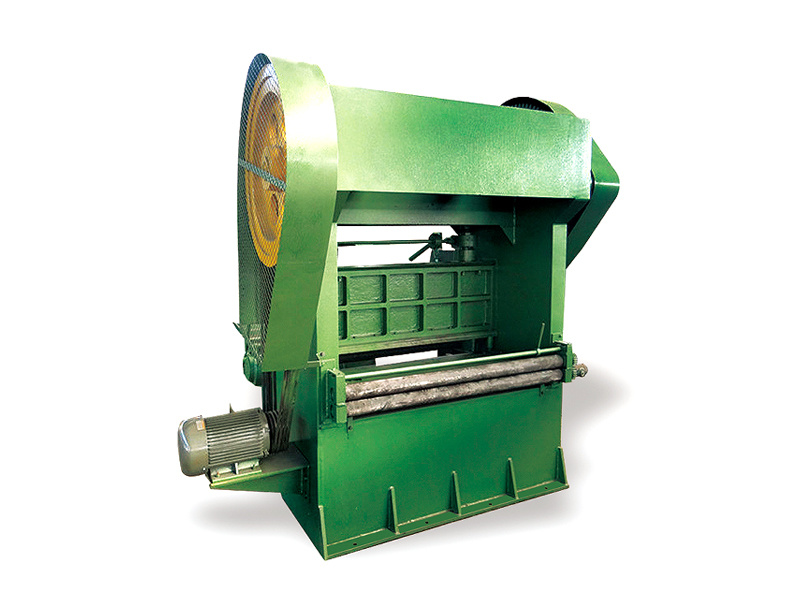

400 automatic spring grinding machine

core technology independent innovation

Category:

Keywords:

Technical Parameters

Slide the table left and right to view all parameters

Equipment introduction

CNC spring grinding machine an intelligent, automatic spring end processing equipment. It can produce 2-4 pieces of spring at the same time, with the functions and advantages of one-click start, large water volume, full closure, automatic slag removal, durable track, servo intelligent feed, process control, and effective prevention of blue. Compared with the traditional spring grinding machine, it has the advantages of high processing precision and fast processing speed, reducing the processing cost and improving the production efficiency and service life.

Device function

1.Can grind springs with outer diameter below 500mm;

2.Manual feed, flexible control of spring grinding feed;

3.The outer cover of the equipment is completely closed and provided with a transparent observation window;

4.High power pump, sufficient water, single pipe 1.5 inches;

5.The left and right swing and grinding wheel feed tooling are outside the protective cover, and can not contact water and sand, and the service life and accuracy of the equipment are greatly improved;

6.The frequency converter controls the motor speed adjustment swing, the fastest 60 times/min, energy saving and consumption reduction at the same time to achieve soft start and soft stop of the motor, effectively alleviating the impact of the swing arm start and stop moment on the cycloidal reducer, prolonging the service life of the equipment;

7.The equipment adopts the upswing structure to reduce the wear of the equipment in the production process, and it is also easier to clean the iron filings and grinding wheel foam generated in the grinding spring process, which greatly improves the production efficiency;

8.Real-time observation of motor current can monitor the operation of grinding wheel motor in real time

9.The motor current overload protection device is mainly used to protect the motor overload, phase break protection and three-phase power imbalance protection, which has a very important protection effect on the motor.

10.With magnetic separator, automatic slag discharge (standby).

Technical parameter

| Serial number | Maximum wire diameter | Maximum outside diameter | Maximum height | Main servo power | Feed mode |

| 1 | 45MM | 260MM | 600MM | 28KW | Double station, manual automatic |

| 2 | 65MM | 400MM | 600MM | 42KW | Double station manual, automatic feed |

Solutions for your products

|

|

|

|

Sales Network

Products are sold all over the country,and exported to the United States,Brazil, India,Mongolia, Southeast Asia and other countries and regions.

Our Advantage

Dongfang Machinery can receive OEM orders

Technology Advantage

Professional technical team with rich production experience, simply provide us with the materials needed or a design drawing, and we will carry out production to meet your needs.

Production Capacity

We have more than 80 sets of machines, including CNC machines , ensuring we can meet production demands quickly.

Quality Control

In order to guarantee the final quality, we utilize advanced production technology, and carry out strict quality testing procedures done by professional inspection staff.

Inquiry

Please leave your contact information so that we can contact you in the first place!

Related Products

Advanced equipment: fuly automatic production line, advanced manufacturing technology, fattening machine, leveling machine, levelingmachine, flat mesh machine, equipment with reasonable mechanical structure, superior perormance, advanced technology, and can beprocessed and customized. The product quality has reached the leading level at home and abroad, making it the best choice to cooperale

with the steel plate drawing machine production line.The winding and unwinding machines produced by our factory are professionally customized based on the customer's provided versionplate material, and plate data.

160T 250T unit group punchingmachine

The steel plate is welded toLongmen structure and equipped with servo automaticfeeding.lt is suitable for continuous production ofwindproof and dust suppression mesh, round hole.square hole, multilateral and irregular mesh, and canalso be used for stamping parts production.

Steel plate is welded to Longmen structureand equipped with step feed. lt is suitable for continuous productionof windproof and dust suppression mesh, round hole, square hole,multilateral and irregular mesh, and can also be used for stampingparts production.