PRODUCTS

CONTACT US

Development Zone Huanghua City Hebei China

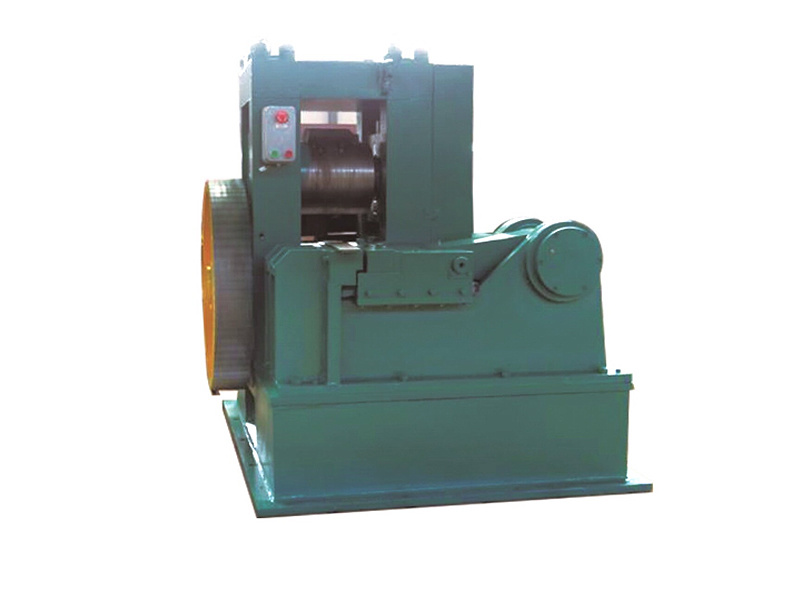

BM-350 Spring Grinding Machine

Item:Number value

Diameter of grinding spring:350MM

Main motor power:15KW- Level 4

Oscillating motor power:1.5KW- Level 4

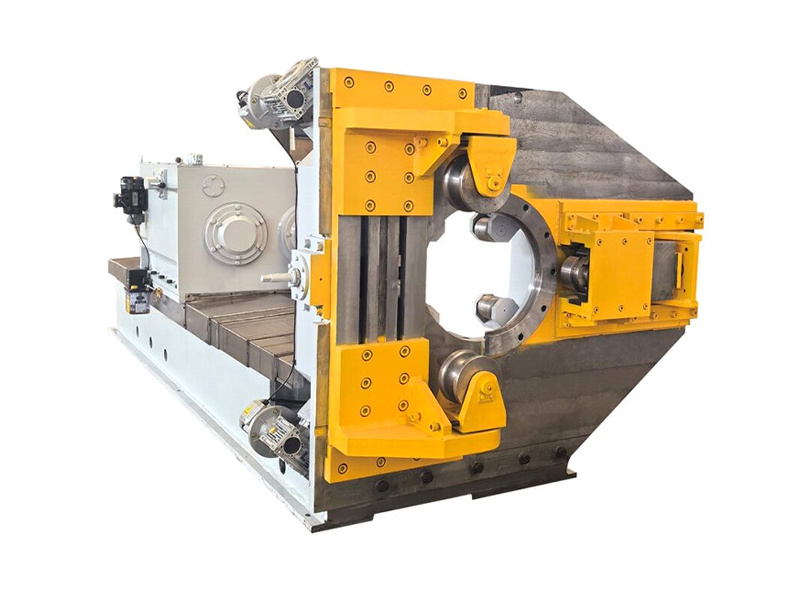

60T automatic spring transverse press

Maximum mandrel diameter:Ф155MM

ADAPTS the outside diameter of the spring:Ф80MM-Ф350MM

Adaptive spring length:150MM-1500MM

BM-500 Spring Grinding Machine

Diameter of grinding spring:500MM

Main motor power:22KW-4 level

Oscillating motor power:2.2KW-4 level

Swing speed control system:Frequency modulation speed regulation

ZM-200 Spring Grinding Machine

Diameter of grinding spring:200MM

Spring grinding station:double-station

Main motor power:15KW- Level 4

Move the motor power:1.5KW- Level 4

CNC hot spring coiling machine is the main equipment for the production of large springs, responsible for the most important coil forming part of large springs in the production link, has the advantages of high production efficiency, less operators and low labor intensity.

Two-axis CNC Cold Coiling Machine

Large diameter CNC cold spring coiling machine is mainly used for small winding ratio, small batch spring winding, can be rolled in the state of non-heating, the maximum diameter of 35mm. Servo motor respectively control the number of spring coil and pitch, the control form is more flexible, the production process can be controlled by programming, the winding speed is adjustable; Multiple springs can be rolled in a single cycle and production can be achieved

Counting, left and right rotation, automatic winding and pitch adjustment.

400 automatic spring grinding machine

CNC spring grinding machine an intelligent, automatic spring end processing equipment. It can produce 2-4 pieces of spring at the same time, with the functions and advantages of one-click start, large water volume, full closure, automatic slag removal, durable track, servo intelligent feed, process control, and effective prevention of blue. Compared with the traditional spring grinding machine, it has the advantages of high processing precision and fast processing speed, reducing the processing cost and improving the production efficiency and service life.

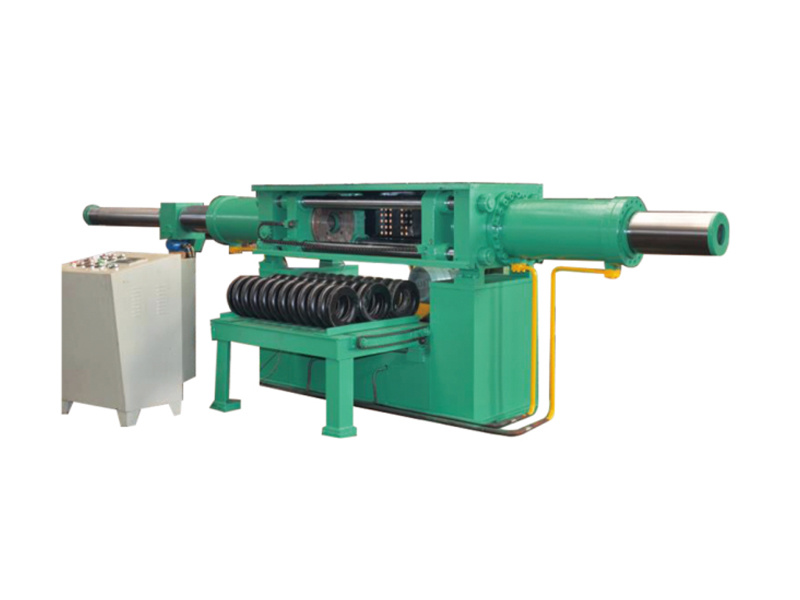

ZPY-80 CNC hydraulic flattening machine

Rolled wire diameter:Ф 20 - Ф 80 mm

Rolling length:≤1500MM

Main motor power:30KW- Level 4

Hydraulic pump motor:22KW-4 level

PY-45 spring end flattening machine

Maximum rolled wire diameter:Ф 45MM

Maximum rolling length:400MM

Main motor power:22KW-4 motor

Rolling pressure:300KN